* Adopt DK core patented technology, ensures the stability and clarity of the prints *Got China national high-speed patents *The fastest ink roll coder in market *Adopt high-speed motor and encoder *Warranty period up to 15 months. *Almost 0 after-sales service needed according to record

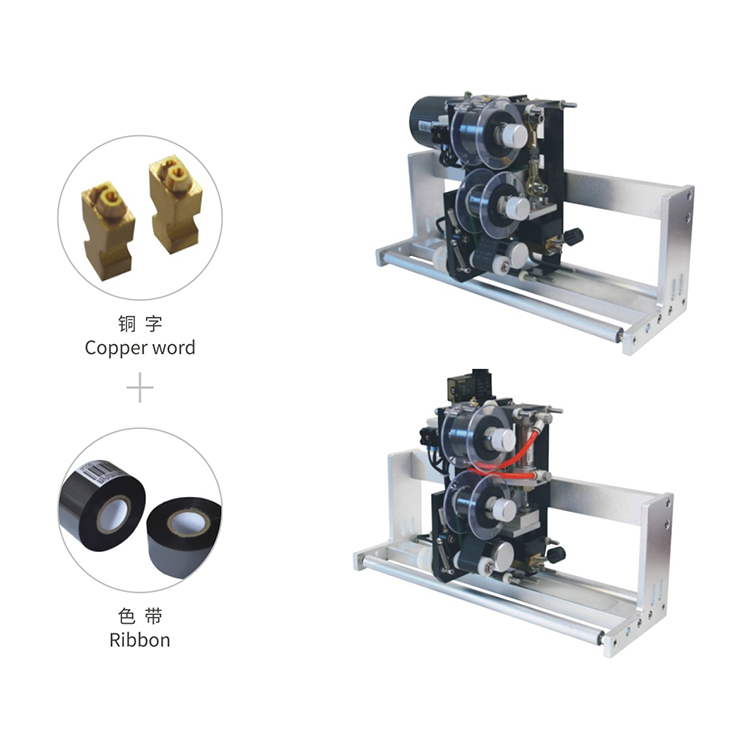

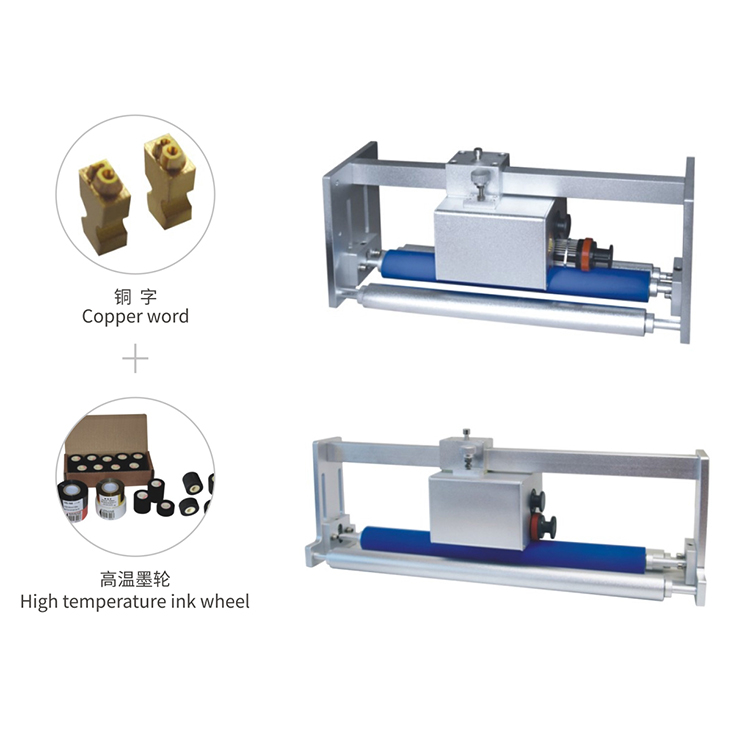

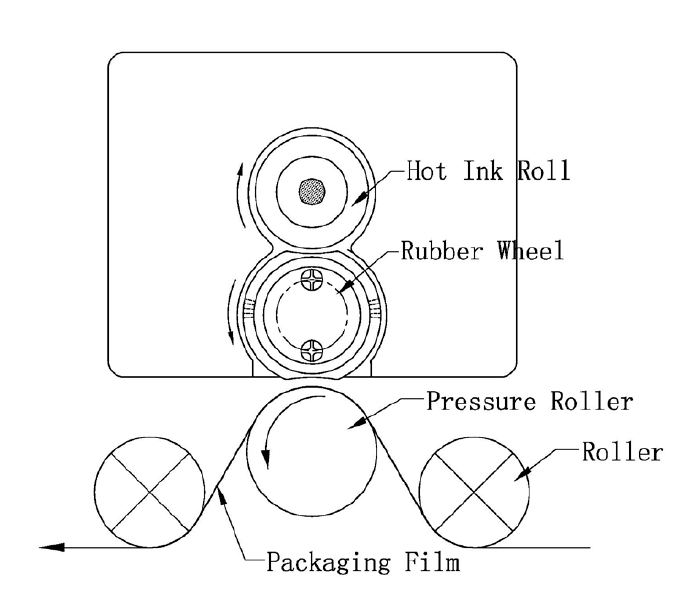

1. The Brass letters contact the Hot Ink Roll and get the ink;

2. The Brass letters are driven by the Rubber Wheel and Pressure Roller to keep moving, then touch the packing film to produce imprint.

3. The Rubber Wheel and Rubber Roller must keep in good contact to ensure the clarity and consistency of the printing.

Please contact us and tell us what products you want to pack. We will recommend the most suitable machine for you.

SYSTEM SOLUTIONS IN THE FIELD OF PACKAGING MACHINE

DESIGN CUSTOM THINK TANK MANUFACTURERS

Packaging & Shipping

DK-1300A Ink roll coder/ Coding Machine

* Adopt DK core patented technology, ensures the stability and clarity of the prints

*Got China national high-speed patents

*The fastest ink roll coder in market

*Adopt high-speed motor and encoder

*Warranty period up to 15 months.

*Almost 0 after-sales service needed according to record

Print area | T-Type (Axial): ≤13 lines; max. 20 characters/line | |

R-type(Radial): ≤10 lines; max. 13 characters/line | ||

Type sizes | T-Type: 1.5T; 2.0T; 2.5T; 3.0T; 2.5*7T | |

R-type: 3.5R; 4.5R; 5.5R | ||

Pouch length | ≥38mm (4-up printer) | |

≥75mm (2-up printer) | ||

Ink roll required | 36*32; 36*35; 36*40mm | |

Electricity | AC220V±10V, 50/60Hz | |

Power | 130W. 2A fuse | |

Weight | Print unit: 4Kgs; Controller box: 2kgs | |