* Most widely used coding machine in the world at present * Adopt technology, ensures the stability and clarity of the prints *Adopting the updated temperature control system, longer service life time. * Warranty period up to 15 months. *Almost 0 after-sales needed according to record

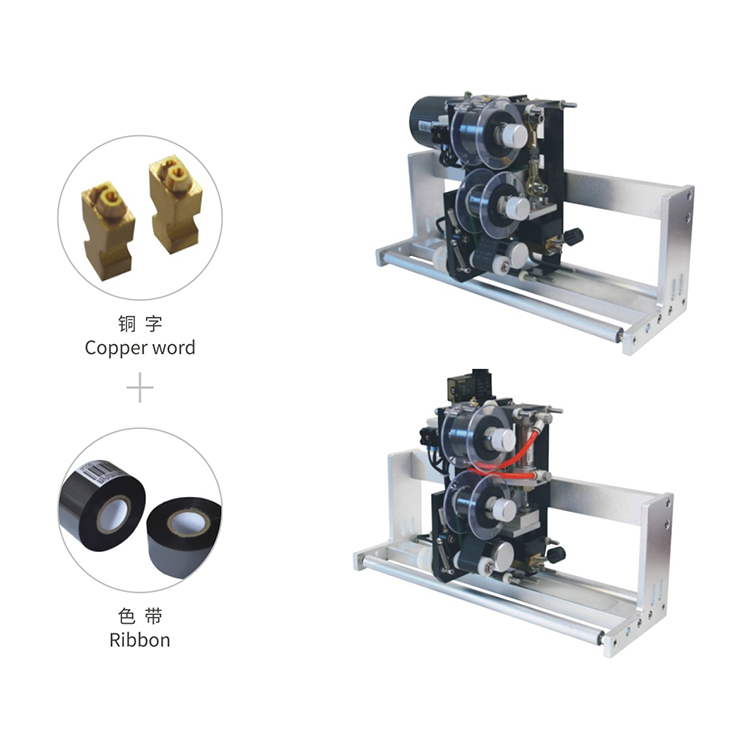

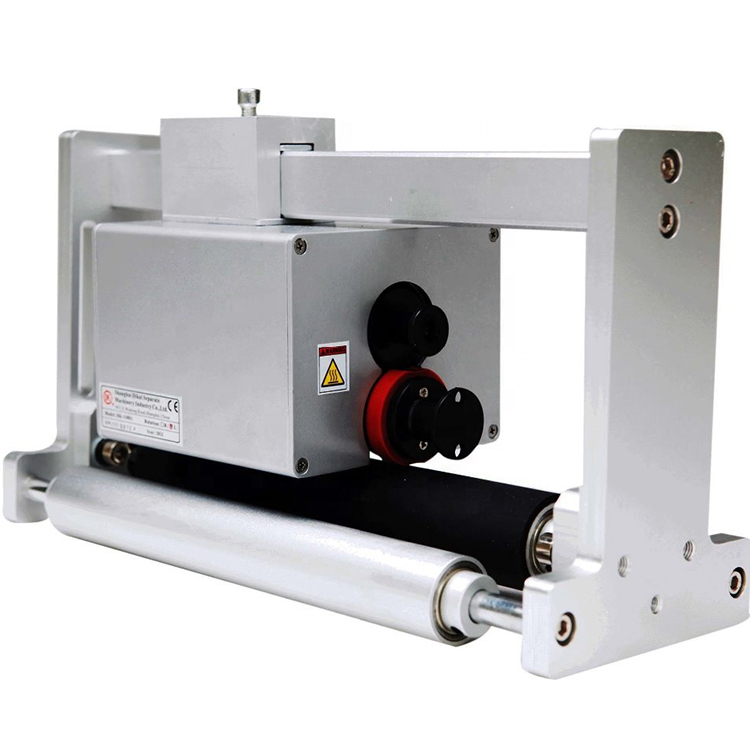

DH-1100A Ink roll coder

* Most widely used coding machine in the world at present

* Adopt technology, ensures the stability and clarity of the prints

*Adopting the updated temperature control system, longer service life time.

* Warranty period up to 15 months.

*Almost 0 after-sales needed according to record

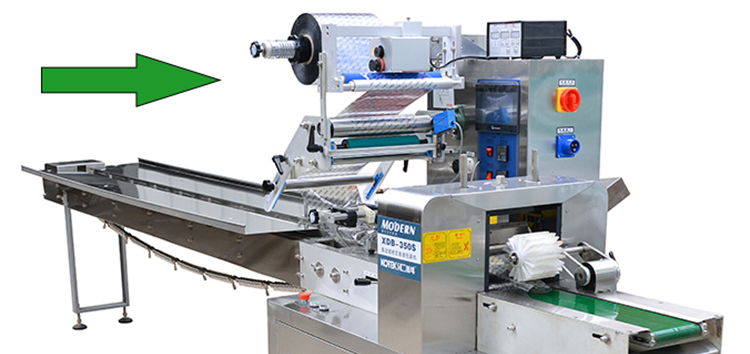

DH-1100A Coding machine Installation

* Purpose built for installing on continuous automatic packaging machine, speed up to 300ppm

*Support various signal modes, ie. PLC, NPN, PNP etc.

* Different print mode for option: Automatic track & Fix delay

*T-shape bracket, easy to install; simple operation

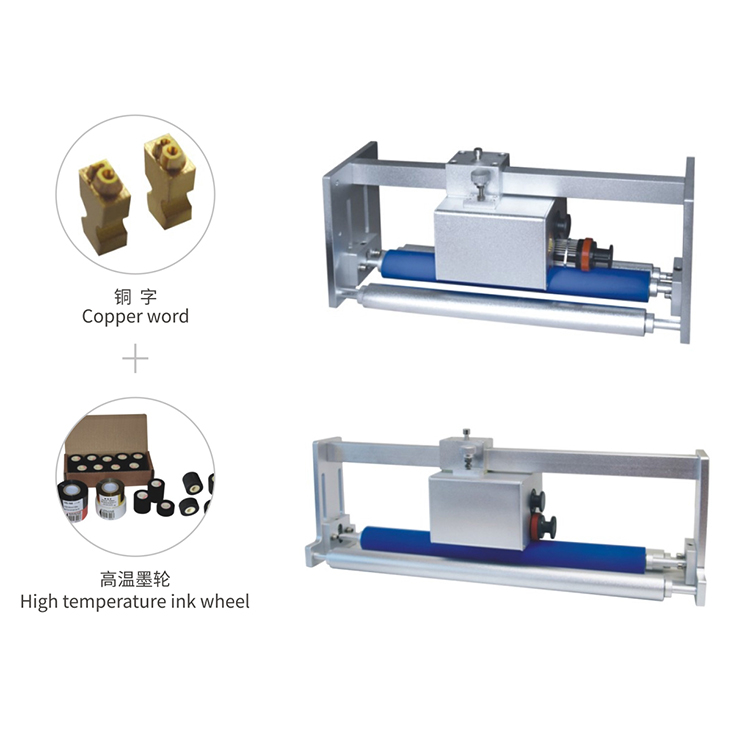

Working Mode 1. The Brass letters contact the Hot Ink Roll and get the ink; |

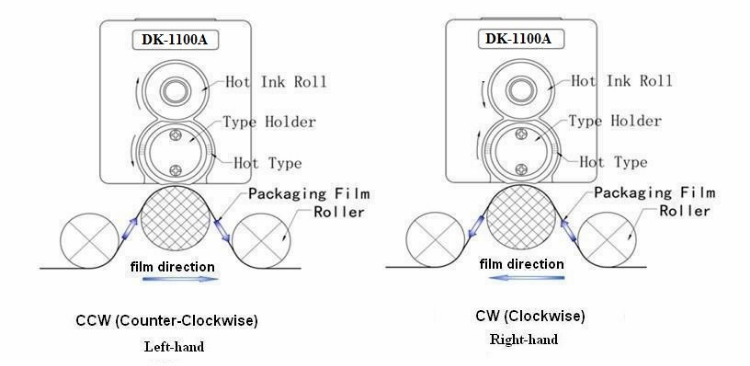

Left/ Right Hand Option Refer to below images, depend on the film direction. Or you can ask colleague for details. |

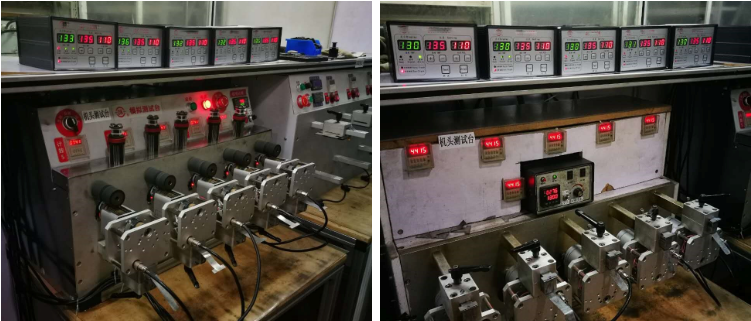

IQC-IPQC-Outgoing Q.C is strictly executed.

To ensure every DH-1100A Automatick Ink Roll Batch Coder Machine you get is up to standard, we test them at least 48 hours before leaving warehouse.

Machine installation dimension drawing: Printer mounting dimension drawing:

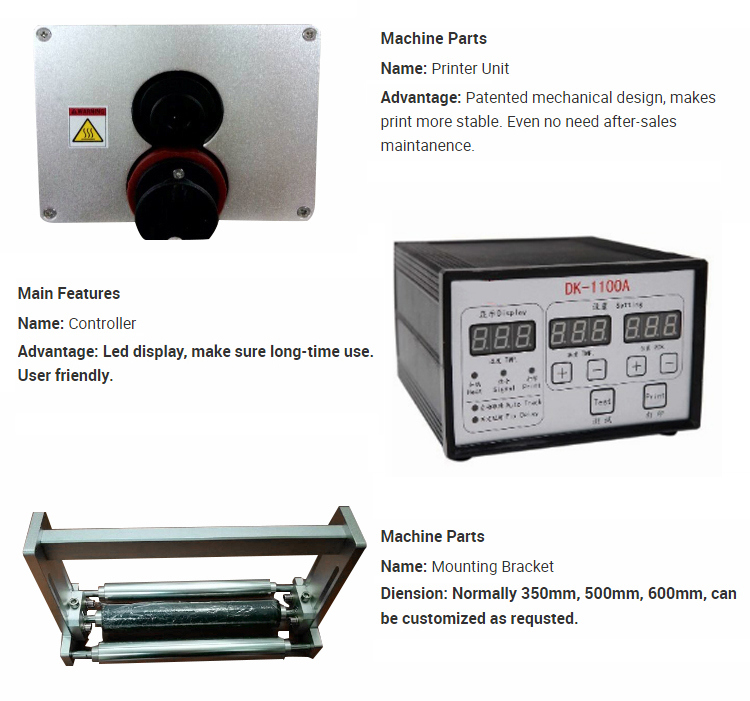

Standard accessories:

Printer | *1 set |

Control box | *1 set |

Installation bracket | *1 pc |

Standard English copper character | *1 box with a tweezers(you can contact us to customize the copper character) |

Printing wheel rack | *1 pc |

Printing ink wheel rack | *1 pc |

Power cord, data line | *1 set |

Ink wheel for testing | *1 piece(Ink wheel is a consumable and needs additional purchase.) |

Adjust tool wrench | *1 set |

Installation fasteners | *1 set |

Other coding machines are optional.

Please contact us and tell us what products you want to pack. We will recommend the most suitable machine for you.

SYSTEM SOLUTIONS IN THE FIELD OF PACKAGING MACHINE

DESIGN CUSTOM THINK TANK MANUFACTURERS

Packaging & Shipping

Package:

Normally in standard export carton packing, can be customized as requested;

Delivery: 1-2 weeks after order confirmation.

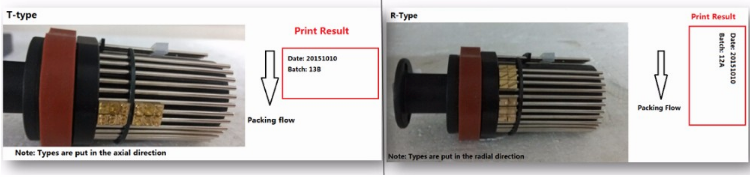

Print area | T-Type (Axial): ≤13 lines; max. 20 characters/line |

R-type(Radial): ≤10 lines; max. 13 characters/line | |

Type sizes | T-Type: 1.5T; 2.0T; 2.5T; 3.0T; 2.5*7T |

R-type: 3.5R; 4.5R; 5.5R | |

Pouch length | ≥38mm (4-up printer) |

≥75mm (2-up printer) | |

Ink roll required | 36*32; 36*35; 36*40mm |

Electricity | AC220V±10V, 50/60Hz |

Power | 130W. 2A fuse |

Weight | Print unit: 2kgs; controller box: 1kg |