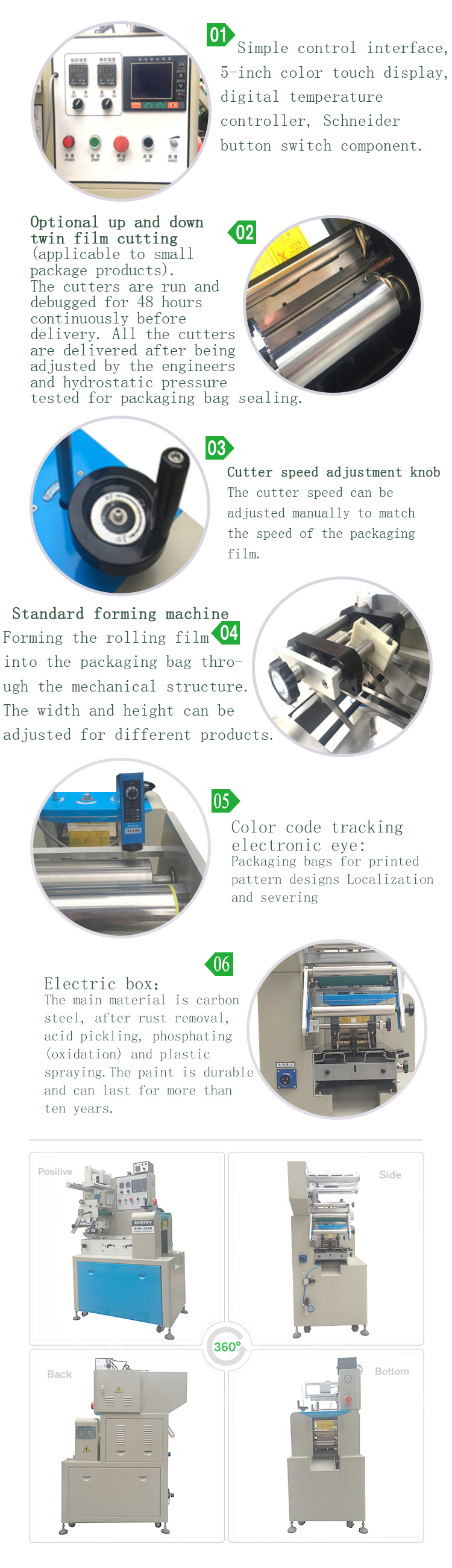

The difference between the traditional paper feeding, the use of paper, especially suitable for preserved fruit, hawthorn, sausage and other sticky and bulk packaging products. The whole machine adopts the servo drive to adjust one step, without wasting the packaging film, saving time and effort The photoelectric tracing is accurate and fast the paper film center's automatically positioned,the operation is convenient and the maintenance is simple

We will run the machine for 24 to 48 hours before shipment.Dual servo system can be upgraded.

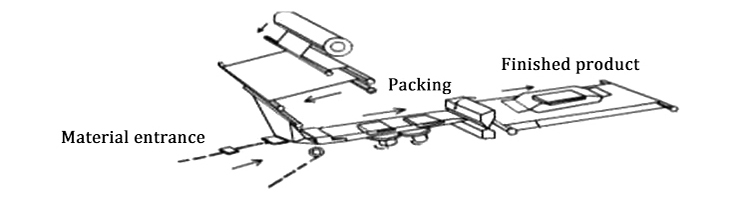

Seamless connection of automatic assembly line (packing product to enter packaging machine)

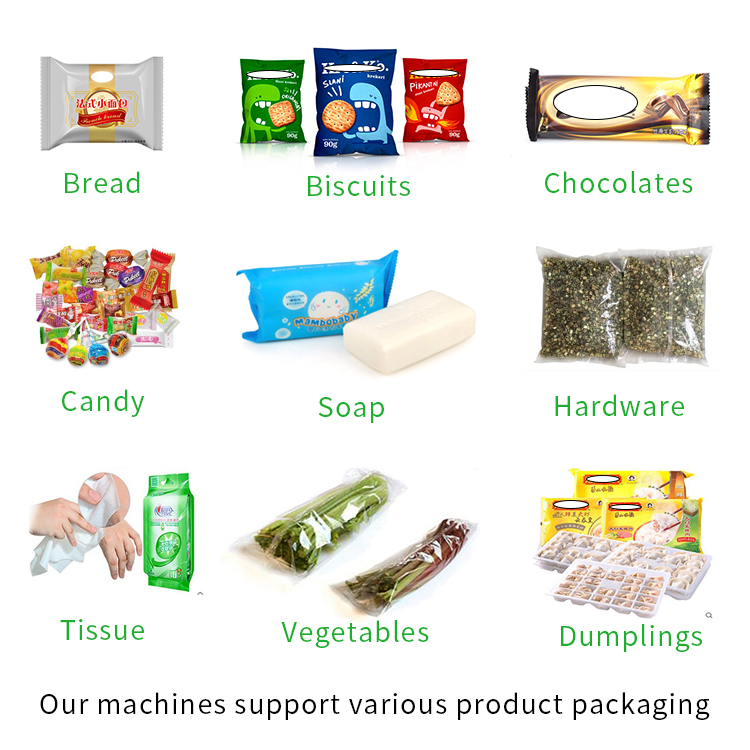

Please contact us and tell us what products you want to pack. We will recommend the most suitable machine for you.

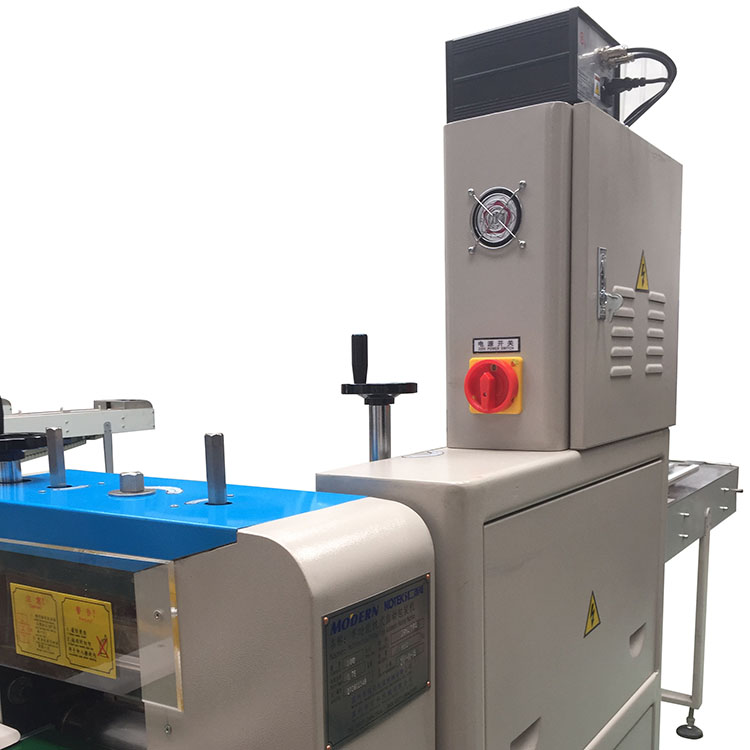

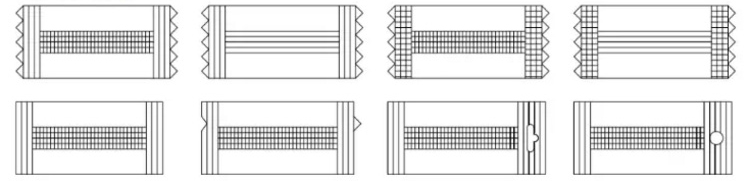

Standard style

SYSTEM SOLUTIONS IN THE FIELD OF PACKAGING MACHINE

DESIGN CUSTOM THINK TANK MANUFACTURERS

Packaging & Shipping

Applicable:

Suitable for packing on viscous and loose products such as preserved fruit, haw chipsausage

Main performance and structure characteristics:

The difference between the traditional paper feeding, the use of paper, especially suitable for preserved fruit, hawthorn, sausage and other sticky and bulk packaging products. The whole machine adopts the servo drive to adjust one step, without wasting the packaging film, saving time and effort The

photoelectric tracing is accurate and fast the paper film center's automatically positioned,the operation is convenient and the maintenance is simple.

Pacing speed(bag/minute) | 30-150 |

Packing Size(mm) | L50-280 W20-100 H5-40 |

Maximum width of film(mm) | 280 |

Thickness of film(mm) | ≥0.025 |

Total power | 3KW |

Rated voltage | 220V |

Rated fmquency | 50HZ |

Weight of the machine | 440KG |

OverallSize(mm) | 3500*670*1520 |

Machine model | Dual servo system | Single servo |

Number of major electrical appliances | Servo motor *2, driver *2, | Servo motor *1, driver *1, deceleration motor *1, |

Main body material of the fuselage | Stainless steel 201(customizable 304) | |

Voltage power | 220v. 50Hz | |

Driving mode | 2 servo motor drive | Single servo motor + ordinary deceleration motor |

Stop the empty package function | yes | no |

Automatic reset function | yes | no |

Install a compound shaper | Standard configuration | Can (add money selection) |

Automatic opening and closing of air seal | yes | no |

Automatic alignment of bearing film shaft | Standard configuration | Can (add money selection) |

Rotary hanger | Standard configuration | no |

Alcohol spray atomizer | Standard configuration | Can (select) |

Matching aeration structure (excluding nitrogen charging system) | Standard configuration | Can (select) |

Can directly match the automatic material packing line of material delivery | yes(can be directly linked to the data line to implement a single machine and | no |

Equipment maintenance cycle | Change the transmission belt (half a year. One year) | Weekly (after three shifts, transmission gear chain, etc.). |