XDB pillow packing machine is a state-of-the-art high speed flow wrapper with a user-friendly human /machine interface control that allows for storing product settings and is very easy to learn which cuts down on operator training. XDB wrapper is loaded with great features that help p...

Please contact us and tell us what products you want to pack. We will recommend the most suitable machine for you.

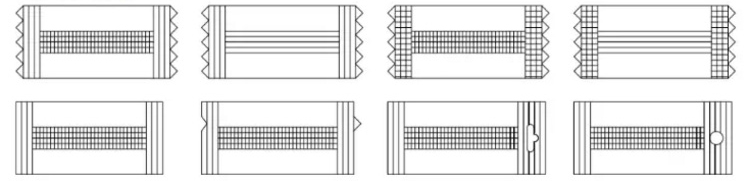

Standard style

SYSTEM SOLUTIONS IN THE FIELD OF PACKAGING MACHINE

DESIGN CUSTOM THINK TANK MANUFACTURERS

Packaging & Shipping

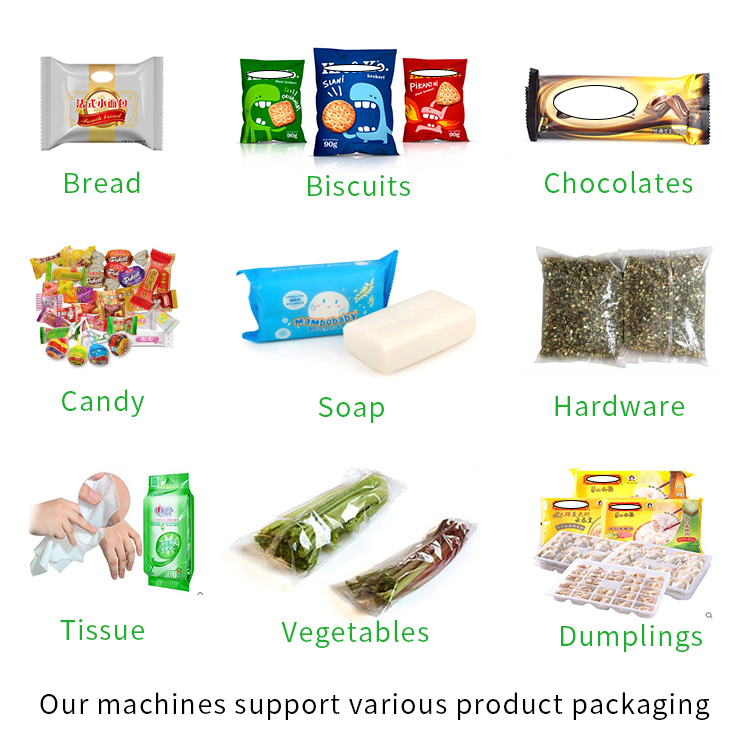

Product Application

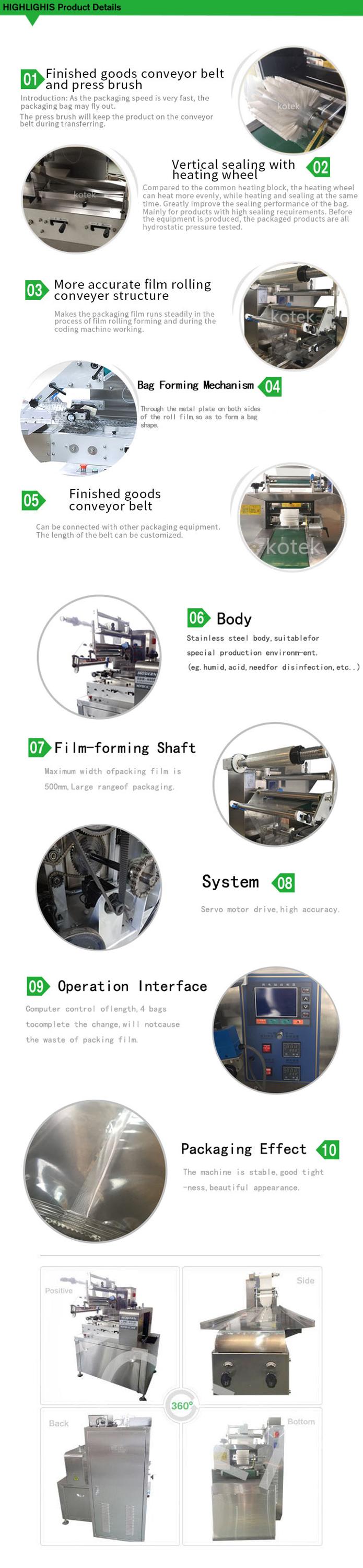

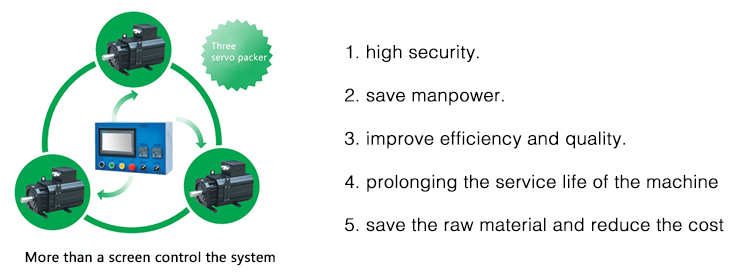

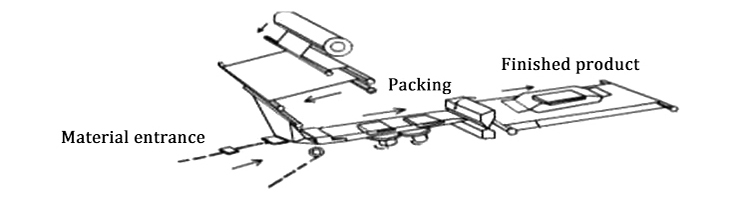

XDB pillow packing machine is a state-of-the-art high speed flow wrapper with a user-friendly human /machine interface control that allows for storing product settings and is very easy to learn which cuts down on operator training. XDB wrapper is loaded with great features that help packagers take their production capabilities to a whole new level. Low noise servo motor driving system for all three independent servo motors.

This machine almost thinks for itself with a sensing function on each servo that prevents products from being damaged if misaligned and a standard no product, no bag (Product detector) feature to reduce film waste.

PRODUCT PRESENTATION | |||

TECHNICAL PARAMETER | Packing speed | (package/min) | 20-240 |

Boundray dimension | (mm) | 4400*940*1600 | |

MAIN PERFORMANCE AND STRUCTRE CHARACTERISTICS | 1.The whole machine is controlled by three servo motor system,improve the operation efficency and service life,simplify the traditional mechanical structure. | 2.Cantilever institutions cooperate with touch scree control system,the operation is simple,maintenance is conwerient. | 3.Mill adjustment is set is cut,don’t have to adjust the speed of cutter,reduce the operating personnel requirements. Automatic roll of film for structure,it is more convenient to adjust. |

APPLICATION |

Suitable for break,cakes,paper towels,medicine,articles for daily use,hardware parts Rules such as the packing of the products. | ||

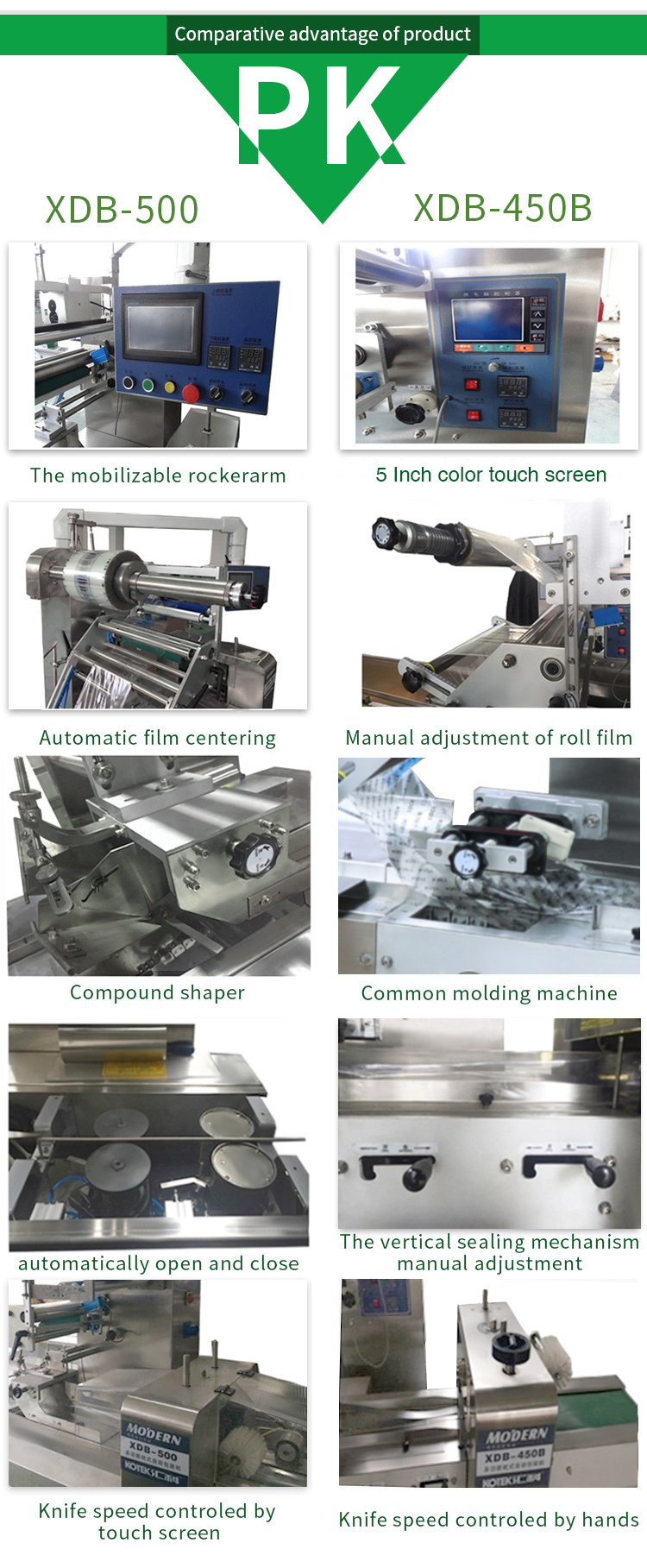

Technical parameter comparison:

Machine model | ||

Number of major electrical appliances | Servo motor *3, driver *3, | Servo motor *1, driver *1, deceleration motor *1, |

Machine size | L4400*W940*H1600 | L4400*W940*H1520 |

Main body material of the fuselage | Stainless steel 201(customizable 304) | |

Weight | 600kg | 550kg |

Voltage power | 220v. 50Hz | |

Packaging size | 500mm | |

Packaging speed | 25-200 bags / minutes | |

Driving mode | 3 servo motor drive | Single servo motor + ordinary deceleration motor |

Stop the empty package function | yes | no |

Automatic reset function | yes | no |

Install a compound shaper | Standard configuration | Can (add money selection) |

Automatic opening and closing of air seal | yes | no |

Automatic alignment of bearing film shaft | Standard configuration | Can (add money selection) |

Rotary hanger | Standard configuration | no |

Alcohol spray atomizer | Standard configuration | Can (select) |

Matching aeration structure (excluding nitrogen charging system) | Standard configuration | Can (select) |

Can directly match the automatic material packing line of material delivery | yes(can be directly linked to the data line to implement a single machine and | no |

Equipment maintenance cycle | Change the transmission belt (half a year. One year) | Weekly (after three shifts, transmission gear chain, etc.). |