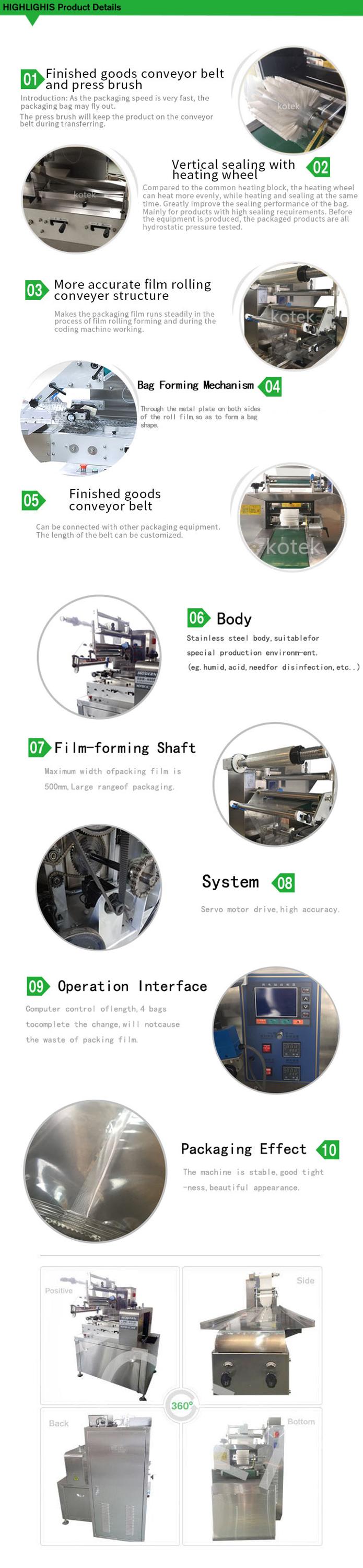

1. User-friendly human/machine interface control for convenient operations. 2. Dialogue type screen provides maximum operation convenience and is easy to learn. 3. Troubleshooting instruction function. Smart control system features self-diagnostic function. 4. Adjustable bag former one unit. 5. ...

Please contact us and tell us what products you want to pack. We will recommend the most suitable machine for you.

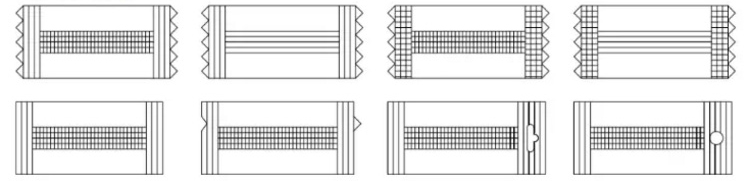

Standard style

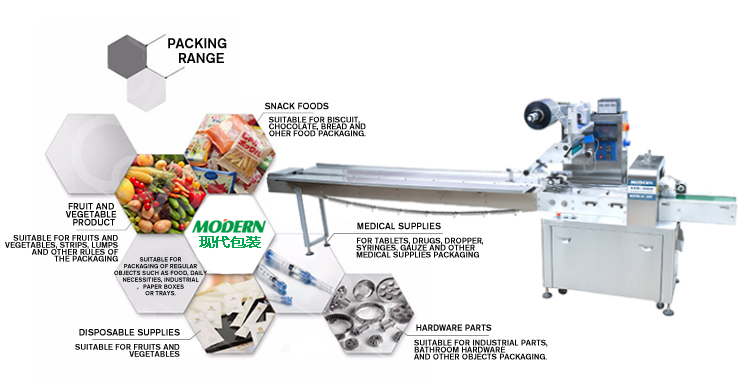

SYSTEM SOLUTIONS IN THE FIELD OF PACKAGING MACHINE

DESIGN CUSTOM THINK TANK MANUFACTURERS

Packaging & Shipping

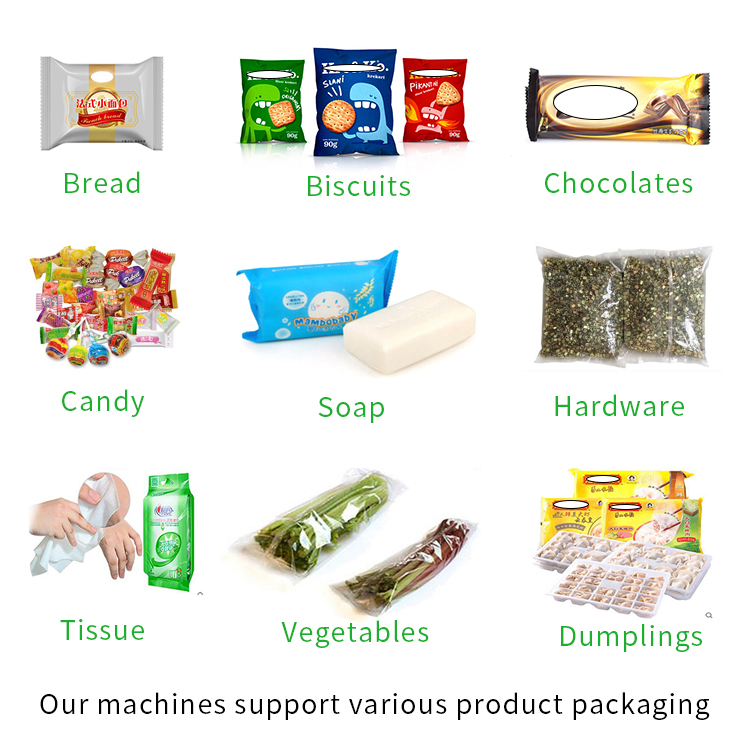

Product Application

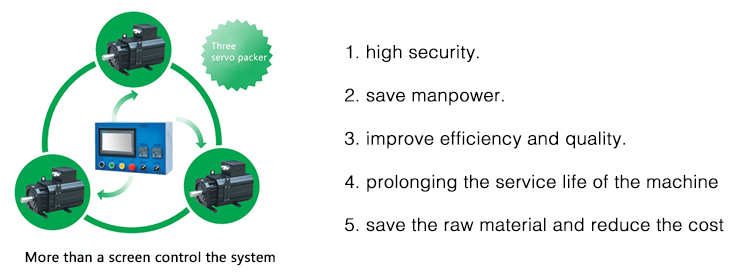

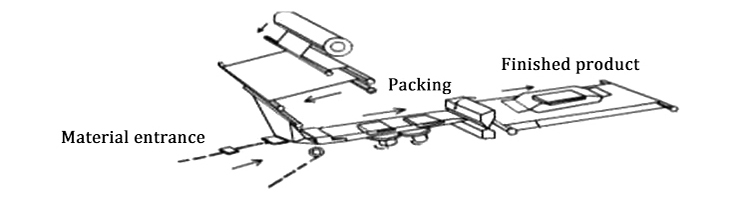

XDB pillow packing machine is a state-of-the-art high speed flow wrapper with a user-friendly human /machine interface control that allows for storing product settings and is very easy to learn which cuts down on operator training. XDB wrapper is loaded with great features that help packagers take their production capabilities to a whole new level. Low noise servo motor driving system for all three independent servo motors.

SPECIFICATIONS FOR XDB-350S

SPECIFICATIONS FOR XDB-350S | |||

Technical parameters | The max. width of packing film | mm | 350 |

Max. height of product | mm | 70 | |

Body material | - | stainless steel | |

This machine almost thinks for itself with a sensing function on each servo that prevents products from being damaged if misaligned and a standard no product, no bag (Product detector) feature to reduce film waste.

Main Features

1. User-friendly human/machine interface control for convenient operations.

2. Dialogue type screen provides maximum operation convenience and is easy to learn.

3. Troubleshooting instruction function. Smart control system features self-diagnostic function.

4. Adjustable bag former one unit.

5. Stainless Steel Construction.

6. “No product, no pack.” When cutting knife cut the product, the cutter will turn automatically.

7. Left to Right operating direction.

8. Rotary cross sealing jaws.

9. 2 Pairs of rollers for longitudinal film pulling and sealing.

10. The bag length is regulated in line with the product length via a photoelectric sensor.

11. Independent temperature controllers for fin and end seals

12. Wrapper: Heat & sealable laminated film, such as OPP,PE POPP, etc.

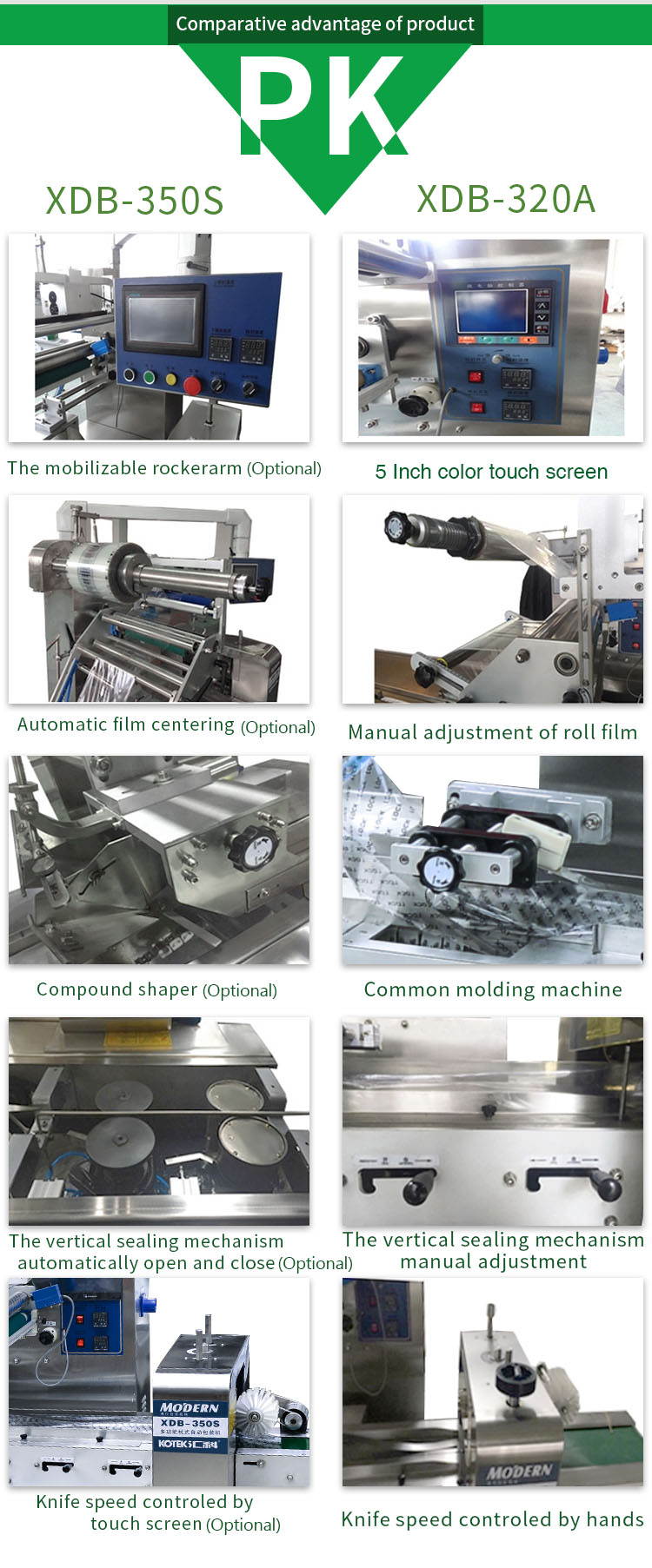

Technical parameter comparison:

Machine model | ||

Motor Power | Sealing servo motor: 1.3kw, feeding motor 0.75kw, film feeding motor 0.75kw, frequency 50HZ | Main motor 0.75kw, servo motor 0.75kw, frequency 50HZ, voltage 220v |

Main body material of the fuselage | Stainless steel 201(customizable 304) | |

Using fastener materials | 8.8GPa 12.9 GPa | |

weight | 480KG | 510KG |

Body standard size (cm) | L440*W87*H152 | |

Applicable packaging film material | Can single-sided heat-sealing packaging film materials (such as OPP, CPP, OPP composite PE, PET composite PE, and other single or composite packaging film materials) | |

Main electrical product specifications | Horizontal sealing heating power 2KWLongitudinal sealing heating power 1KW | |

Packaging film size range, thickness range | Film width 350mm Film thickness 0.025mm | |