One set of photoelectric, horizontal and darts detection are adopted to facilitate switching and selection. For thin and small packaging, it is also easy to complete the sealing packaging Automatic feeding, the length can also be automatically adjusted by a combination of an electric ey...

Configure the difference:

| Model+A | Model+L | Model+C |

| Mechanical control panel | PLC control panel | Structure with seal (mechanical panel) |

Performance feature:

* One set of imported photoelectric detection, horizontal detection and darts detection are adopted to facilitate switching and selection; For thin and small packaging, it is also easy to complete the sealing packaging

* Automatic feeding, the length can also be automatically adjusted by a combination of electric eye and timer. Equipped with induction motor, automatic winding waste

* When the size of the package is changed, the package size can be adjusted by turning the handwheel. It is very easy to adjust the size without changing the mold and bag maker;

* Products of different sizes can also be combined with packaging to achieve promotional effects;

* Use the original "Autonix" built-in PD function digital display temperature controller. Sealing knife temperature is extremely sensitive and accurate, colleagues can also set at will; There is no need to worry about the temperature is not accurate damage products, sealing knife itself also has automatic protection function, can effectively prevent the wrong cut packaging

* The sealing and cutting part of the machine is equipped with plexiglass protective cover and has automatic alarm function, which greatly improves the operator's safety;

* The whole set of machines are truly connected with the unmanned operation of the production line

* Specially designed film up and down synchronization mechanism to correct film deviation

* The function of easy tearing can be added according to customers' requirements

* Conveying adopts a new type of roller shaft with imported fiber sleeve, which is resistant to high temperature, wear, hot film and deformation, and can be used for a long time. The roller shaft can be turned or not to meet the shrinkage requirements of different products;

* This machine is suitable for POF,PVC,PP and other shrinkage film.

Application area:

Suitable for software, food, cosmetics, printing, pharmaceutical, floor, ceramic, beverage and hardware industries such as large volume shrink packaging

BS-4522N adaptive shrinking machine performance characteristics:

* Electronic governor is adopted for speed regulation, and the conveying speed can be adjusted arbitrarily to ensure the conveying smoothness and good shrinkage effect;

* Digital display computer intelligent temperature control, small temperature difference stable and reliable, low noise, long life;

* High quality stainless steel heating tube

* Good heat insulation effect, set power off function to avoid heat dissipation

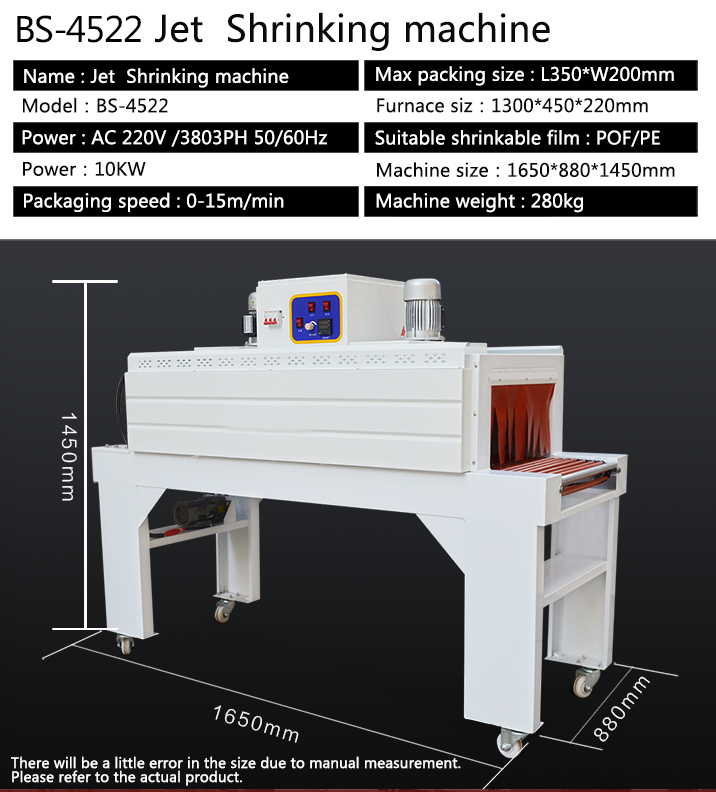

Technical parameters:

| model | FL-450 | FL-550 | FL-750 |

| power | 1.5KW | 2.2KW | 3.5KW |

power source | AC220V 1/3PH 50/60H | AC220V 1/3PH 50/60H | AC220V 1/3PH 50/60H |

| package size | L550*W450mm | L650*W550mm | L850*W750mm |

| sealing size | <500mm | <600mm | <800mm |

| packaging speed | 15-30bag/min | 15-30bag/min | 15-30bag/min |

| air source | 6-8kg/m³ | 6-8kg/m³ | 6-8kg/m³ |

| shrink film | POF/PE | POF/PE | POF/PE |

| machine size | 1650*880*1450mm | 1750*900*1450mm | 1950*1200*1550mm |

| weight | 280kg | 350kg | 550kg |